“The most important part of any mechanical lifting equipment is the inside workings – not what they look like on the outside. Just because something looks the same on the outside – does not mean they are made the same on the inside”, commented Glenn Morgan, KITO PWB National Hoist Specialist.

With the KITO load chain, you are always in safe hands. A quality that delivers what it promises!

KITO is one of the few companies that manufactures both its hoists and its load chains. On top of that – KITO is the only manufacturer worldwide that nickel-plates its load chains. This combination provides the hoists with the unique benefit of safety and functionality, and excellent reliability.

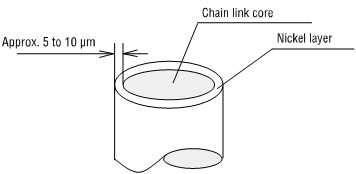

The precise manufacturing quality of KITO products is realized by following demanding production and inspection procedures that exceed the highest existing international safety standards. Therefore, KITO load chains are in demand in all parts of the world. KITO’s nickel-plating process prevents hydrogen embrittlement, as the chain material can be penetrated by hydrogen molecules. Thanks to its special properties, nickel is especially well suited as a surface coating for many applications, such as the windmill and offshore industries.

Profile

The load chains are electroless nickel-plated and feature an increased corrosion and abrasion resistance in comparison to zinc-plated load chains. The nickel-plated load chains characterize a breaking strength of 800 or 1000 N/mm2 respectively and bring additional advantages to the user such as wear-resistance and long service life.

Features

High tensile steel has a hydrogen embrittlement issue which reduces its strength when zinc electro-plating absorbs hydrogen into the steel. KITO has been preventing this embrittlement risk by generating less hydrogen and eliminating absorbed hydrogen.

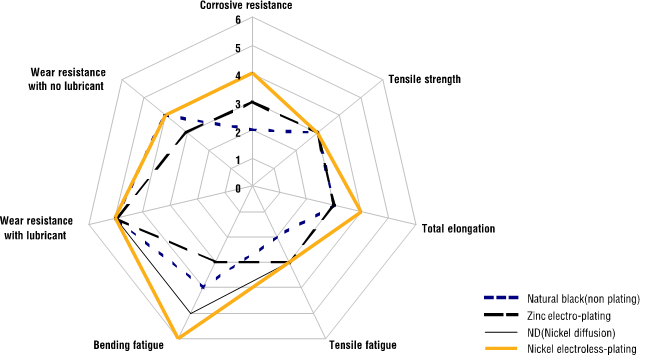

The new nickel electroless-plated chain compared to the former chain features outstanding resistance to bending fatigue and improved properties, for instance, corrosive resistance, total elongation, and wear resistance with no lubrication (however, lubricant needed for use). It is also better protected against hydrogen embrittlement. The chart below shows the case-hardened chain properties for various surface treatments. (This chart may differ for varying chain diameters or operational conditions.)

Chart: Case-hardened Chain Property vs Surface Treatments (zinc electro-plating basis)

The load chains comply with the quality class DAT or V, respectively. KITO’s load chains fully comply with the standard AS1418.2 and have been certified by the trade association BGHM (Institution for Statutory Accident Insurance and Prevention in the Woodworking and Metalworking Industries). Furthermore, KITO received for all its produced load chains the official certification stamp H23.

Salt Spray Test

Below are the pictures of the Nickel-plated chain VS Zinc-plated chain after sprayed with 5% saltwater continuously for 120 hours to check rust. Rust is equal to metal is being melted. If significant rust occurs on chains, there is a high possibility that the chain may break. The consequence is to disassembling the hoist and replacing the chains which will require extra workload and cost.

Product advantages

- The only company that manufactures both its hoists and its nickel-plated load chains

- According to Australian Standard AS1418.2

- Longer service life

- High reliability

- Minimal maintenance

Features

- Electroless nickel-plated

- High wear resistance

- High corrosion resistance(hard to rust)

- Strong against hydrogen embrittlement

- Two categories of KITO load chains: classification of the chains into load chains for manual chain products and load chains for electric chain hoists

- Chains for manual chain hoists: Quality class T, Grade mark V (G100 – 1000 N/mm²)

- Chains for electric chain hoists: Quality class T, Grade mark DAT (G80 – 800 N/mm²)

Options

- Various types of KITO load and hand chains from stainless steel are available on request.

- For KITO’s build-to-order capabilities please contact our sales team at 1300 792 262

Extract from the Germany publication:

Hebezeuge Fördermittel 48/2008

Impressive advantages…. that’s what really sets you apart from your competitors. KITO is the only manufacturer worldwide that nickel-plates its load chain. This process of the surface coating does not involve gassing because the nickel surface is permeable to hydrogen molecules. Nickel is well known for its resistance to salty air, water, diluted acids, and most lye.